A 3D printer machine creates three-dimensional objects layer by layer from a digital file. It uses various materials, including plastic, metal, and resin.

Understanding the revolutionary impact of 3D printing technology begins with recognizing its versatility and efficiency. This innovative tool has transformed industries, allowing for rapid prototyping, complex design production, and customization previously unachievable with traditional manufacturing methods. Its applications range from medical implants to automotive parts, showcasing its vast potential.

Entrepreneurs, hobbyists, and educators alike embrace 3D printing for its ability to bring ideas to life quickly and cost-effectively. As technology advances, the implications for future developments in manufacturing, healthcare, and even space exploration continue to expand, marking 3D printing as a cornerstone of modern engineering and design innovation.

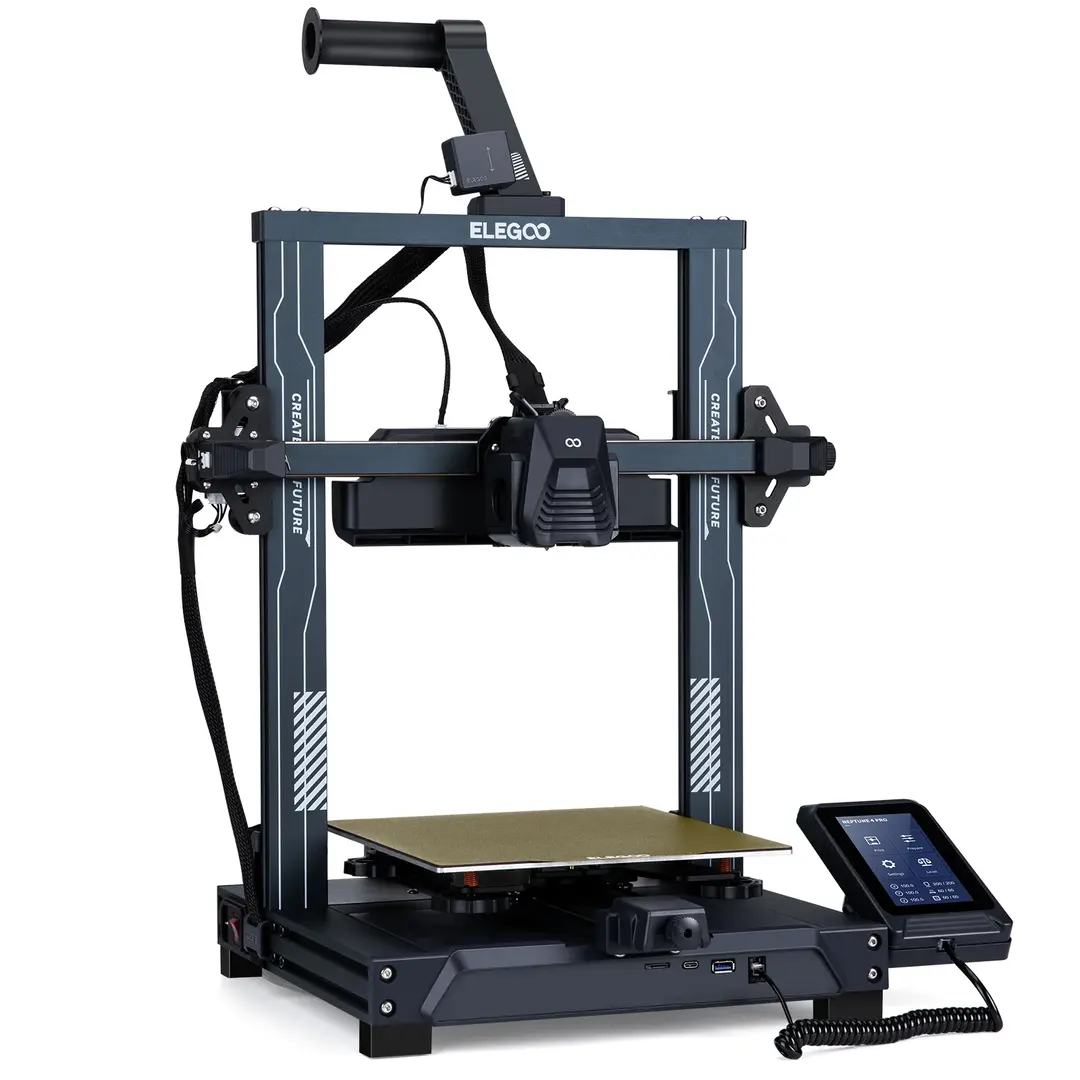

| Image | Title | Buy |

| ELEGOO Neptune 3 Pro FDM 3D Printer with Auto Bed Leveling, Dual-Gear Direct Extruder, Dual Lead Screw Drive, Removable Capacitive Screen, 8.85×8.85x11in Large Printing Size | AMAZON |

| ZONESTAR New Upgrade 4 Extruder 4-IN-1-OUT Mix Multi Color Large Size High Precision Resolution 3D Printer DIY Kit Z8PM4Pro MK2 | AliExpress |

Credit: all3dp.com

Introduction To 3d Printing

3D printing is a transformative technology. It turns digital designs into physical objects. This process is also known as additive manufacturing. Layers of material are printed to create complex shapes. The technology has evolved rapidly. It offers exciting possibilities across various fields.

The Evolution Of 3d Printers

The first 3D printers emerged in the 1980s. They were large and expensive. Today, they are more accessible and versatile. Innovations have led to improved speed, accuracy, and material variety. From hobbyists to professionals, the evolution of 3D printers has been remarkable.

Impact On Industries

- Healthcare: Custom implants and prosthetics are now possible.

- Aerospace: Durable, lightweight parts can be made with less waste.

- Construction: Buildings and structures are printed with concrete.

- Automotive: 3D printing enables rapid prototyping and customization.

- Education: Students learn about manufacturing and design in a hands-on way.

Read More: Home & Garden

Types Of 3d Printers

Exploring the world of 3D printing unveils a variety of machines. Each type caters to different needs. Let’s dive into the most popular types.

Fused Deposition Modeling (fdm)

FDM is a common 3D printing method. It’s great for beginners. The process uses thermoplastic filaments. These are heated and extruded through a nozzle. Layer by layer, your design takes shape.

- Cost-effective: Ideal for small businesses and hobbyists.

- Versatile: Prints with various materials.

- User-friendly: Easy to use and maintain.

| Pros | Cons |

|---|---|

| Low material cost | Lower resolution |

| Simple operation | Visible layer lines |

Stereolithography (sla)

SLA stands for precision and detail. It uses a laser to harden liquid resin. The result is very smooth surfaces.

- Great for intricate models.

- Produces high-quality prints.

- Used in dentistry and jewelry making.

This technology needs careful handling. Resin can be messy. It also requires proper ventilation.

| Pros | Cons |

|---|---|

| High precision | Expensive materials |

| Smooth finishes | Requires post-processing |

Key Components Of A 3d Printer

Understanding the key components of a 3D printer is crucial. These parts work together to bring digital models to life. Let’s dive into two main components: the Print Bed and Frame, and the Extruder Mechanics.

Print Bed And Frame

The print bed is where your object takes shape. It’s the surface on which the printer lays down material. A good print bed should be level and stable. This ensures your creations are precise and accurate.

The frame holds all parts of the 3D printer together. It must be strong. A solid frame means less vibration. Less vibration leads to smoother prints.

- Material: Print beds can be made of glass, metal, or other materials.

- Heating: Some print beds heat up. This helps the first layer stick better.

Extruder Mechanics

The extruder is the heart of a 3D printer. It pushes material out to create objects. There are two main types: direct and Bowden.

Direct extruders are close to the print head. They work well with flexible materials. Bowden extruders are further away. They can move faster since they are lighter.

- Nozzle: This is where the material comes out. Nozzles can have different sizes.

- Motor: It drives the filament through the extruder.

- Fan: Keeps the extruder at the right temperature.

Credit: www.3ding.in

Choosing The Right Material

Choosing the Right Material for your 3D printer is key. The material affects the print’s strength, flexibility, and durability. Let’s explore popular choices.

Pla And Abs

PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are common materials. Both have unique advantages.

- PLA is biodegradable and easy to use. It’s perfect for beginners.

- ABS is strong and heat-resistant. Ideal for functional parts.

Choosing between PLA and ABS depends on your project needs. PLA is eco-friendly. ABS is tough.

Advanced Materials

For specific projects, advanced materials offer unique properties.

| Material | Properties | Uses |

|---|---|---|

| PETG | Strong, flexible | Outdoor parts |

| TPU | Flexible, durable | Phone cases |

| Nylon | Tough, wear-resistant | Gears, hinges |

Advanced materials like PETG, TPU, and Nylon expand possibilities. They suit specific needs.

Designing For 3d Printing

Designing for 3D Printing unlocks endless creative possibilities. Transform ideas into reality with precision and ease. This journey begins with two critical steps: choosing the right software and adhering to design best practices.

Software Choices

Success in 3D printing starts with selecting appropriate software. Various options cater to different skill levels and needs.

- TinkerCAD – Ideal for beginners, offers an intuitive interface.

- SketchUp – Versatile for hobbyists, with extensive plugins.

- Fusion 360 – Professional choice, combines power with precision.

Consider compatibility, user support, and community size when selecting software.

Design Best Practices

Follow best practices to ensure designs are print-ready and reliable.

| Practice | Benefit |

|---|---|

| Wall Thickness | Prevents breaks, maintains structure. |

| Overhangs | Limit to 45 degrees to avoid supports. |

| Assembly | Design in parts for easy assembly. |

Maintain a balance between aesthetic and functional aspects. Test and iterate designs for best results.

Post-processing Techniques

Once you’ve printed your 3D model, it’s time to make it shine with post-processing. This step transforms your print from a rough draft into a polished piece. Let’s explore the techniques to achieve that perfect finish.

Sanding And Painting

Sanding smooths your print’s surface. Begin with coarse sandpaper. Gradually move to finer grits. This method erases print lines and prepares the surface for painting.

Painting adds color and protects your model. Use a primer first. Follow with acrylic or spray paint. Always paint in thin, even coats.

| Step | Action | Tip |

|---|---|---|

| 1 | Start with coarse sandpaper (100-200 grit) | Wear a mask to avoid inhaling dust. |

| 2 | Progress to finer sandpaper (200-400 grit) | Check progress often to avoid over-sanding. |

| 3 | Apply primer to ensure paint adhesion | Let primer dry completely before painting. |

| 4 | Paint in thin coats, allowing drying time | Use multiple light coats for the best finish. |

Chemical Finishing

Chemical finishing gives a smooth, glossy surface. Use solvents like acetone for ABS plastic. Apply with a brush or dip your model. Always work in a well-ventilated area.

- Use gloves and eye protection for safety.

- Apply solvent in a well-ventilated space.

- Brush solvent evenly across the surface.

- Allow the model to dry and cure fully.

Note: Chemical finishing can be dangerous. Read all instructions and safety data sheets (SDS) before starting.

Troubleshooting Common Issues

Troubleshooting common issues with 3D printers is a vital skill for users. Knowing how to fix problems can save time and frustration. Here are some tips for dealing with the most common issues.

Bed Adhesion Problems

Bed adhesion is crucial for a successful print. If prints don’t stick, they might warp or fail. Follow these steps to fix bed adhesion issues:

- Check the bed level; it should be even.

- Clean the bed with isopropyl alcohol to remove grease.

- Apply adhesives like glue stick or hairspray for extra grip.

- Adjust bed temperature based on filament type.

Nozzle Clogs

Nozzle clogs can stop your prints mid-way. Look out for these signs:

| Sign | Action |

|---|---|

| Under-extrusion | Clean the nozzle |

| Clicking sounds | Check for filament tangles |

| Print pauses | Inspect for blockages |

To unclog a nozzle:

- Heat the nozzle to soften the filament.

- Use a needle to clear the blockage.

- Perform a ‘cold pull’ to remove residue.

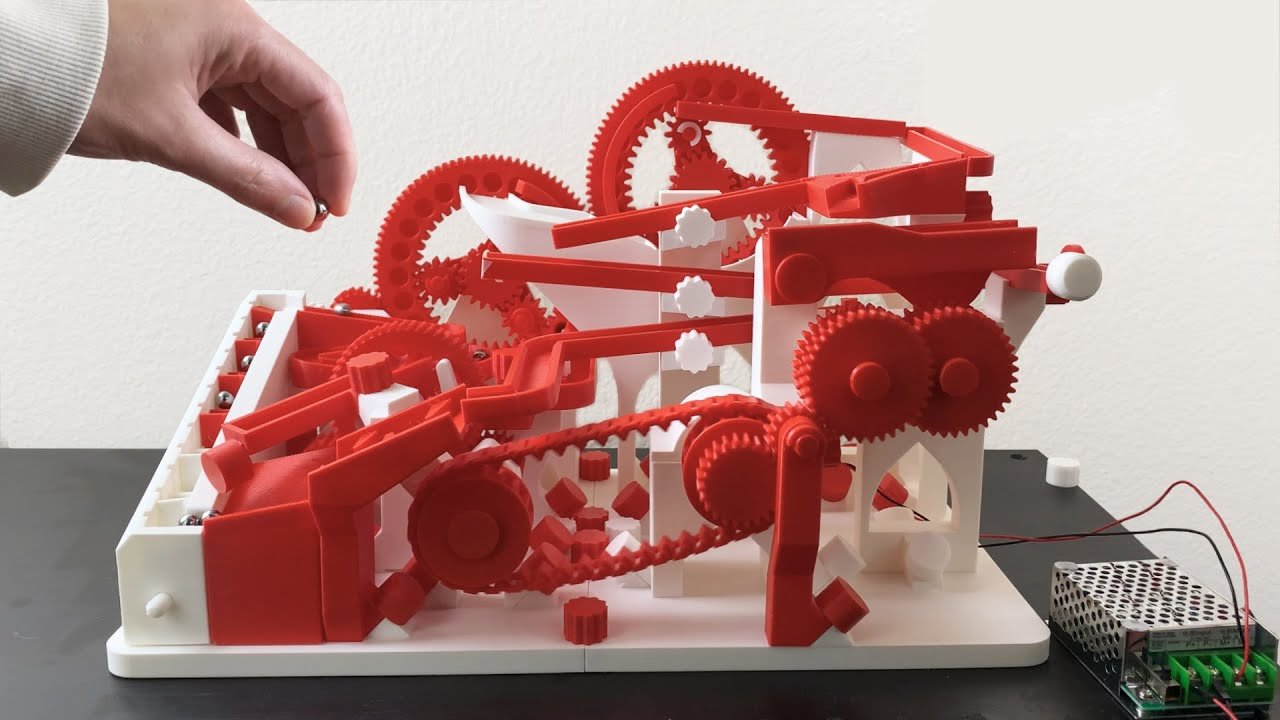

Expanding Your Creativity With 3d Printing

Expanding Your Creativity with 3D Printing unlocks a new realm of possibilities. Whether you’re an inventor, artist, or hobbyist, 3D printing technology allows you to bring your ideas to life. Imagine, design, and create objects that were once thought impossible. Let’s explore how this innovative tool is revolutionizing creativity.

Prototyping And Customization

3D printers excel in turning visions into tangible prototypes. Designers and engineers can iterate rapidly, perfecting their creations. This speed transforms product development.

- Quick iterations mean faster refinement

- Lower costs compared to traditional methods

- Ability to customize on the fly

Art And Fashion Applications

Artists and fashion designers use 3D printers to push boundaries. Intricate designs and complex geometries are now possible. Unique art pieces and wearable fashion items come to life with 3D printing.

| Art | Fashion |

|---|---|

| Custom sculptures | Innovative accessories |

| Personalized jewelry | Haute couture pieces |

Credit: www.popsci.com

Frequently Asked Questions

What Is A 3d Printer Machine Used For?

3D printers are used to create three-dimensional objects by layering materials. They serve various industries, including manufacturing, healthcare, and education, facilitating rapid prototyping, custom parts creation, and complex design production.

How Does A 3d Printer Work?

A 3D printer works by extruding molten material, often plastic, layer by layer, to build up a 3D object. The design is sliced into thin layers, which the printer follows, creating the object from the bottom up.

What Materials Can 3d Printers Use?

3D printers can use a range of materials, including plastics like PLA or ABS, metals, ceramics, and even living tissue. The choice of material depends on the printer type and the desired object’s properties.

How Much Does A 3d Printer Cost?

The cost of a 3D printer can vary widely, from under $200 for basic models to over $10,000 for industrial-grade printers. The price depends on the printer’s size, capabilities, and the technology it uses.

Conclusion

Embracing the innovation of 3D printing technology opens a realm of possibilities. Whether you’re a hobbyist or a professional, a 3D printer can revolutionize your creative workflow. As we’ve explored, these machines offer precision, versatility, and the power to bring ideas to life.

Start your 3D printing journey today and witness your imaginations materialize before your eyes.