Logistics and Supply Chain Management (SCM) involves the efficient movement of goods from suppliers to consumers. It focuses on optimizing processes to enhance customer satisfaction and reduce costs.

Logistics and Supply Chain Management are essential components of modern business operations. They encompass the planning, execution, and control of the flow of products and services. Effective logistics ensures timely delivery and efficient inventory management. Supply chain management integrates various stakeholders, including suppliers, manufacturers, and retailers, to streamline processes.

This collaboration improves efficiency and reduces operational costs. Businesses that master SCM can respond quickly to market demands, gaining a competitive edge. In today’s fast-paced market, understanding these concepts is crucial for success. Companies that prioritize logistics and SCM can enhance customer satisfaction and drive profitability.

Role Of Logistics

Logistics plays a critical role in the world of Supply Chain Management. It ensures that goods move smoothly from suppliers to customers. Efficient logistics helps businesses save time and money. It also improves customer satisfaction by delivering products on time. Understanding the role of logistics is essential for any business aiming to thrive in a competitive market.

Functions In Supply Chain

Logistics encompasses several key functions in the supply chain. These functions work together to ensure efficient movement of goods. Below are the main functions:

- Transportation: Moving goods from one location to another.

- Warehousing: Storing products until they are needed.

- Inventory Management: Keeping track of stock levels.

- Order Fulfillment: Processing customer orders accurately and quickly.

- Packaging: Protecting products during transit.

Each function contributes to the overall efficiency of the supply chain. A table below summarizes these functions:

| Function | Description |

|---|---|

| Transportation | Moves goods to different locations. |

| Warehousing | Stores products until they are needed. |

| Inventory Management | Tracks stock levels to prevent shortages. |

| Order Fulfillment | Processes orders accurately and quickly. |

| Packaging | Protects goods during transportation. |

These functions are vital for maintaining a seamless flow of products. Efficient logistics reduces delays and costs, which benefits the entire supply chain.

Impact On Business Operations

The impact of logistics on business operations is profound. Effective logistics enhances productivity and efficiency. It helps businesses meet customer demands swiftly. A few key impacts include:

- Cost Reduction: Efficient logistics lowers transportation and storage costs.

- Improved Customer Satisfaction: Timely deliveries lead to happier customers.

- Better Inventory Control: Accurate tracking prevents overstock and stockouts.

- Increased Flexibility: Quick adjustments to changes in demand.

Efficient logistics can significantly influence a company’s bottom line. Companies that invest in logistics often see greater profits. A table below illustrates how logistics impacts different areas of business:

| Area | Impact |

|---|---|

| Cost | Lower operational costs. |

| Customer Service | Higher satisfaction ratings. |

| Inventory | More efficient stock management. |

| Adaptability | Faster response to market changes. |

Logistics is a backbone for successful business operations. Strong logistics practices lead to better performance and growth.

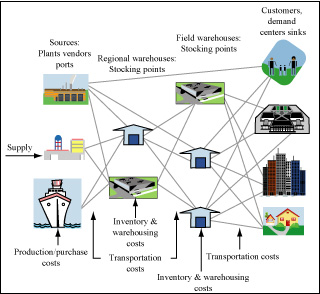

Credit: ocw.mit.edu

Supply Chain Components

Logistics and Supply Chain Management are vital for businesses. They ensure that products move smoothly from producers to consumers. Understanding the supply chain components helps companies operate better. Key components include procurement processes and distribution networks. These elements work together to deliver goods efficiently.

Procurement Processes

Procurement is the process of acquiring goods and services. It involves several important steps that help companies get what they need. Here are the main steps:

- Identifying Needs: Determine what products or services are required.

- Supplier Selection: Find reliable suppliers who can deliver quality goods.

- Negotiation: Discuss prices and terms with suppliers.

- Ordering: Place orders for the needed items.

- Receiving: Accept and check the goods upon delivery.

- Payment: Complete payment for the received items.

Each step is crucial for a smooth procurement process. A table can help visualize the steps:

| Step | Description |

|---|---|

| Identifying Needs | Recognize what is necessary for operations. |

| Supplier Selection | Choose suppliers based on quality and reliability. |

| Negotiation | Discuss terms and reach an agreement. |

| Ordering | Submit orders for products or services. |

| Receiving | Inspect goods after delivery. |

| Payment | Pay for the items received. |

Efficient procurement processes save time and money. They also improve the quality of goods received.

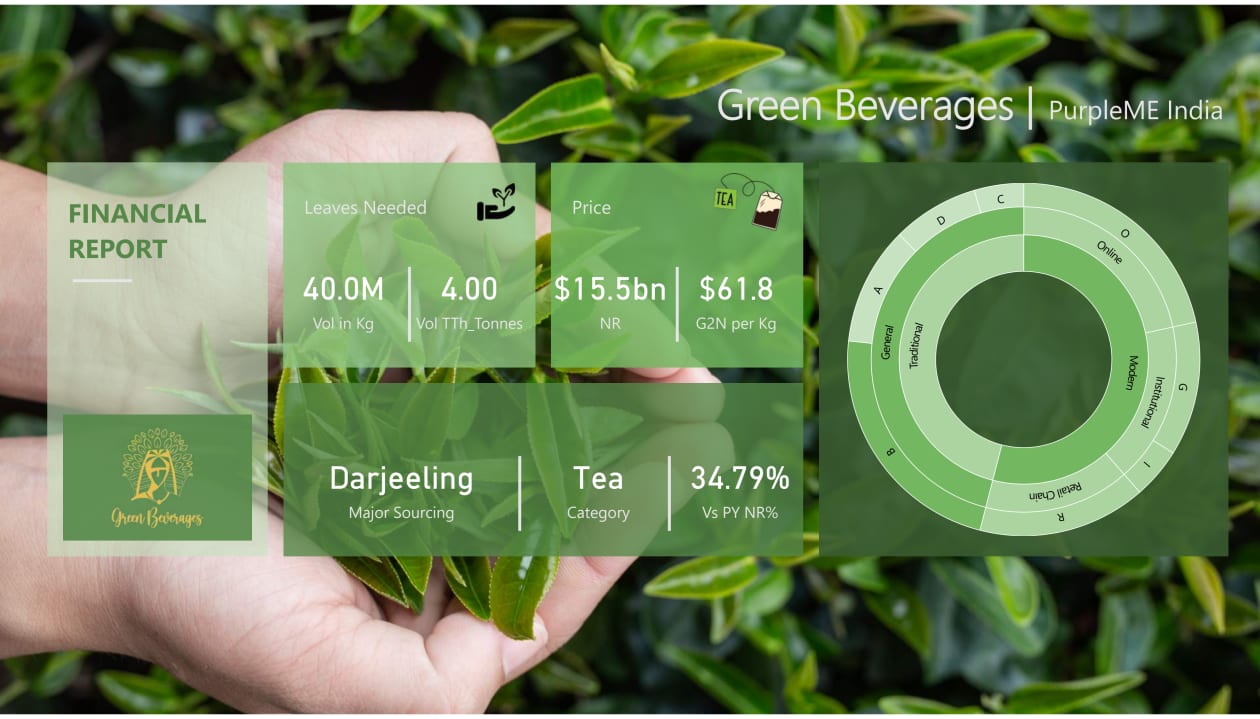

Credit: fiverr.com

Distribution Networks

Distribution networks are essential for delivering products to customers. They include various channels to transport goods efficiently. A good distribution network ensures products reach the right place at the right time.

Key elements of distribution networks include:

- Warehousing: Storing goods until they are needed.

- Transportation: Moving products from one location to another.

- Order Fulfillment: Preparing and delivering orders to customers.

Distribution networks can be complex. They involve multiple steps to ensure effective delivery. Here’s a simple breakdown:

- Receive inventory at warehouses.

- Prepare items for shipment.

- Load goods onto transportation vehicles.

- Transport items to their destination.

- Deliver products to customers.

Each step in the distribution network is important. Efficient networks improve customer satisfaction and reduce costs. Companies must continuously evaluate their distribution strategies to stay competitive.

Technology In Logistics

Technology plays a crucial role in logistics and supply chain management. It helps businesses move goods faster and more efficiently. With the right tools, companies can save time and money. Technology also enhances decision-making and improves customer satisfaction. Businesses that embrace technology can stay ahead of their competition.

Automation Tools

Automation tools are essential in modern logistics. They help reduce manual work and increase efficiency. These tools streamline processes and improve accuracy. Here are some key benefits of automation:

- Reduced Human Error: Fewer mistakes lead to fewer delays.

- Increased Speed: Tasks are completed faster.

- Cost Savings: Lower labor costs and fewer errors save money.

Common automation tools include:

| Tool | Description |

|---|---|

| Warehouse Management Systems (WMS) | Tracks inventory and manages warehouse operations. |

| Transportation Management Systems (TMS) | Optimizes shipping routes and manages freight. |

| Robotic Process Automation (RPA) | Automates repetitive tasks in logistics. |

These tools help companies improve their supply chain operations. They save time and reduce costs. Automation is a game-changer in logistics.

Credit: relevant.software

Data Analytics

Data analytics is transforming the logistics industry. It helps companies make smart decisions based on real-time data. Businesses can track shipments, monitor inventory, and predict demand. This leads to better planning and fewer surprises.

Key advantages of data analytics include:

- Improved Forecasting: Predict future demand accurately.

- Enhanced Visibility: Track shipments in real-time.

- Better Customer Insights: Understand customer preferences and trends.

Companies can use various data analytics tools:

| Tool | Purpose |

|---|---|

| Business Intelligence Software | Analyzes data for better decision-making. |

| Predictive Analytics Tools | Forecasts future trends and behaviors. |

| Real-time Analytics Platforms | Provides immediate insights into operations. |

By leveraging data analytics, companies can enhance their logistics performance. They can respond to changes quickly and meet customer needs effectively.

Credit: fiverr.com

Challenges In Supply Chain

Logistics and Supply Chain Management face many challenges. These challenges impact how goods move from producers to consumers. Understanding these issues helps businesses improve their operations. Two major challenges are global disruptions and cost management.

Global Disruptions

Global disruptions can greatly affect supply chains. Events like natural disasters, pandemics, and political unrest cause delays. These disruptions can lead to:

- Product shortages: Fewer goods available for customers.

- Increased delivery times: Longer waits for shipments.

- Higher prices: Costs rise due to limited supply.

For example, the COVID-19 pandemic caused many factories to shut down. This led to delays in shipping and increased prices. Companies need to prepare for these disruptions.

Here’s a simple table showing examples of global disruptions:

| Event | Impact on Supply Chain |

|---|---|

| Natural Disasters | Damage to infrastructure and delays in shipping. |

| Pandemics | Factory closures and workforce shortages. |

| Political Unrest | Trade restrictions and increased shipping costs. |

To tackle global disruptions, companies can:

- Diversify suppliers: Use multiple sources for materials.

- Invest in technology: Improve tracking and communication.

- Create contingency plans: Prepare for unexpected events.

Cost Management

Cost management is crucial in supply chain management. Companies must keep costs low while maintaining quality. Rising costs can squeeze profits and affect pricing. Some factors that influence costs include:

- Fuel prices: Higher fuel costs increase shipping expenses.

- Labor costs: Salaries and benefits impact overall spending.

- Raw material prices: Fluctuations can affect production costs.

Smart businesses monitor these costs closely. They analyze spending and look for savings. Here are some effective cost management strategies:

- Negotiate with suppliers: Seek better prices for materials.

- Optimize inventory: Reduce excess stock to cut costs.

- Utilize technology: Use software to track expenses.

By focusing on cost management, companies can improve their bottom line. They can offer competitive prices while maintaining quality. This balance is key to success in the supply chain.

Read More: Graphic Design Examples for Beginners: Inspiring Your Creativity

Future Trends

Logistics and Supply Chain Management (SCM) play a vital role in our economy. They ensure products reach consumers smoothly. The future trends in this field promise exciting changes. Businesses are focusing on efficiency and customer satisfaction. They are also looking to improve their impact on the environment. Let’s explore the future trends in logistics and supply chain management.

Sustainability Initiatives

Businesses are increasingly adopting sustainability initiatives. They aim to reduce their environmental footprint. Here are some key practices:

- Eco-friendly Packaging: Companies use biodegradable materials.

- Carbon Offsetting: They invest in projects that reduce emissions.

- Efficient Transportation: Using electric vehicles and optimizing routes helps cut fuel use.

Many organizations are shifting toward green logistics. They focus on minimizing waste and conserving resources. This shift benefits both the planet and the bottom line.

| Initiative | Benefit |

|---|---|

| Recycling Programs | Reduces waste and saves costs |

| Energy-efficient Warehouses | Lowers energy bills |

| Alternative Fuels | Decreases reliance on fossil fuels |

These practices create a win-win situation. They help the environment while improving company reputation. Consumers prefer brands that care about sustainability.

Emerging Technologies

Emerging technologies are reshaping logistics and supply chain management. Artificial Intelligence (AI) and Blockchain are leading this change. They enhance efficiency and transparency.

- AI: Predicts demand and optimizes inventory.

- Blockchain: Provides secure and real-time tracking of goods.

- Internet of Things (IoT): Connects devices for better data collection.

Robots and automation are also on the rise. They handle repetitive tasks, allowing human workers to focus on complex issues.

| Technology | Impact |

|---|---|

| AI | Improves decision-making |

| Blockchain | Enhances security |

| IoT | Boosts efficiency |

These technologies create smarter supply chains. They help companies respond faster to market changes. Staying ahead of these trends is crucial for success.

Credit: m.youtube.com

Credit: www.michiganstateuniversityonline.com

Frequently Asked Questions

Is Logistics And Supply Chain A Good Major?

Logistics and supply chain management is a strong major with high demand. Graduates often find diverse career opportunities and competitive salaries. The field emphasizes problem-solving and efficiency, making it ideal for those interested in operations and strategy. Overall, it offers a promising career path for students.

What Does A Logistics And Supply Chain Manager Do?

A logistics and supply chain manager oversees the flow of goods from suppliers to customers. They coordinate transportation, inventory management, and warehousing. This role ensures efficiency, reduces costs, and improves service quality. Managers also analyze data to enhance supply chain processes and maintain supplier relationships.

What Is The Work In Logistics And Supply Chain?

Logistics and supply chain work involves managing the flow of goods from suppliers to customers. It includes transportation, warehousing, inventory management, and order fulfillment. Professionals ensure timely delivery and efficiency, optimizing processes to reduce costs and improve customer satisfaction. Strong communication and coordination skills are essential in this field.

What Degree Do You Need For Logistics?

A bachelor’s degree in logistics, supply chain management, or business administration is typically required. Some positions may accept an associate degree or relevant experience. Advanced roles often prefer a master’s degree in logistics or an MBA with a focus on supply chain management.

Certifications can enhance job prospects.

Conclusion

Effective logistics and supply chain management are crucial for business success. Streamlined processes enhance efficiency and reduce costs. Companies that prioritize these areas gain a competitive edge. Embracing technology and innovation can further optimize operations. Focus on building strong partnerships for lasting growth and improved customer satisfaction.

Your supply chain can drive your business forward.

Read More: Graphic Design Examples for Beginners: Inspiring Your Creativity